Quick Tips

| Cutters | |

|---|---|

| CUTTER CAUTION Storing cutters Don’t leave cutters loose in a drawer or tool bag, as they are likely to get chipped and Read the full article... |

| CUTTER CLEANING If you clean your cutters immediately after use, especially if you have been cutting resinous softwood, the resin will still Read the full article... |

| CUTTER CAUTION Removing bearings from cutters A gardening glove can be used the first time you remove the bearing from a bearing-guided Read the full article... |

| CUTTER CAUTION Removing cutters from box Some boxed sets are packaged in very tight-fitting plastic inserts and it is easy to cut Read the full article... |

| Machine Setting | |

| DIFFERENT LENGTH BUSHES If your guide bushes are longer as the diameter increases, as they are with the Bosch quick-release bushes, you can’t Read the full article... |

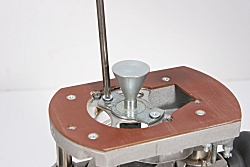

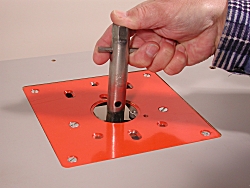

| CENTRING/ ALIGNMENT CONE A centring cone is very useful for aligning guide bushes and for checking the concentricity of your router base with Read the full article... |

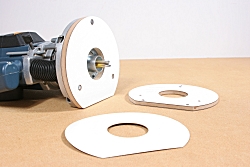

| CENTRING BUSHES Not all routers allow adjustment of the guide bush. Those with plain fixing holes and nut-and-bolt fixing usually do. With Read the full article... |

| TWIST-KNOB PLUNGE LOCK It is very easy to twist the wrong knob when locking the plunge on routers such as the DeWalt DW613, Read the full article... |

| THREE-STAGE TURRET Many routers have what’s described as a three-stage turret for setting depth of cut in easy stages. Many of these Read the full article... |

| SETTING DEPTH OF CUT Many popular router models have very simple depth setting, with no provision for zeroing a scale. A quick and accurate Read the full article... |

| Maintenance | |

| ROUTER MAINTENANCE Plunge lock lever With routers with lever plunge lock, such as the DeWalt DW625, the lever has to be pushed Read the full article... |

| PLUNGE LEG MAINTENANCE Fortunately for us, the router is an extremely low-maintenance tool, but there are a few obvious things we can do Read the full article... |

| CLEANING AIR VENTS The air vents on top of the router body should be kept free of dust to facilitate cooling. A paint Read the full article... |

| PLUNGE LOCK MAINTENANCE Plunge lock knobs and levers apply a soft brass alloy pellet to the plunge leg to lock the plunge. With Read the full article... |

| COLLET AND MOTOR SPINDLE MAINTENANCE Keep the collet clean by brushing loose dust away with a little brush, and cleaning off resinous deposits with a Read the full article... |

| WORKSHOP BRUSHES Various kinds of brush can be used for all sorts of odd jobs in the workshop, quite apart from applying Read the full article... |

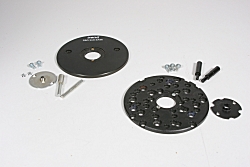

| LONG BUSHES Most big routers come with a 30mm guide bush as standard. One reason for this is that one of the Read the full article... |

| Router Table Tips | |

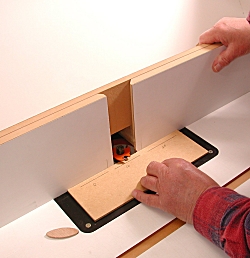

| ADJUSTABLE FENCE STOPS With many router table applications the shape or size of the cutter precludes making light cuts by raising it in Read the full article... |

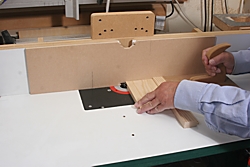

| VERTICAL PUSH BLOCK With router table work you often need to pass the workpiece vertically past the cutter. A tall table fence helps, Read the full article... |

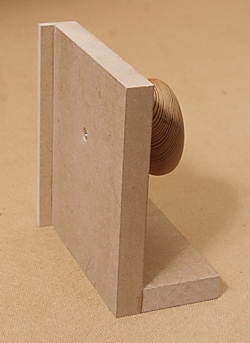

| RIGHT-ANGLE PUSH BLOCK WITH BREAKOUT PROTECTION I do not use a mitre fence on my router table for the reasons given in the ‘Mitre Fence’ entry Read the full article... |

| HANDLES FOR WORK AIDS Many routing work aids are easier to use if they have a substantial handle with which to guide them. Read the full article... |

| TABLE FENCE If your table fence has separate infeed and outfeed fences, you can shim the outfeed fence to bring it forward Read the full article... |

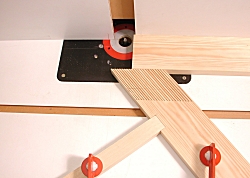

| PRESSURE GUARDS You can make your own horizontal pressure guards by cutting the end of a softwood board at about 45 degrees Read the full article... |

| BISCUIT JOINTING If you have a 4mm slotter you don’t need a bearing on it to set depth of cut for biscuiting. Read the full article... |

| SETTING PIECES When setting up a complex cutter for the first time, e.g. a profile/scriber or a lock mitre cutter, the job Read the full article... |

| MITRE FENCE If your router table is fitted with a mitre fence and you want to use the table fence to control Read the full article... |

| ADJUSTING THE FENCE Very fine adjustments to the router table fence can be made by pivoting it at one end on one of Read the full article... |

| Routing Basics | |

| BOX SPANNERS One of the problems of using a router in a table is that it can be difficult to insert and Read the full article... |

| GUIDE BUSHES With guide bush work, if you’re using a bush of small diameter, make sure that your depth of cut isn’t Read the full article... |

| PUSHING & PULLING Beginners are sometimes puzzled as to whether a router should be pushed or pulled. As long as the router is Read the full article... |

| THROUGH CUTS As a general safety measure, always check that your cutter is not in contact with the workpiece before switching on. Read the full article... |

| RATE OF FEED A common error of the newcomer to routing is to feed the router too slowly into the workpiece. This gives Read the full article... |

| CORRECT DIRECTION OF CUT The router should be propelled in the direction usually described as ‘against the rotation of the cutter’. The cutter rotates Read the full article... |

| CUTTER SPEEDS If you have a variable speed router, set the motor speed according to the diameter of your cutter and the Read the full article... |

| Routing Techniques | |

| CUTTING IN THE WRONG DIRECTION Despite there being a ‘correct’ direction of cut, there are a number of occasions when it’s advantageous to cut in Read the full article... |

| FIVE TIPS FOR BASIC DOVETAIL JIGS Using a fine height adjuster A fine height adjuster – of the kind that prevents the router rising on its Read the full article... |

| Workshop | |

| MORE USES FOR THE ROUTER MAT With routing, perhaps more than with other branches of woodwork, holding the workpiece is sometimes the most difficult part of Read the full article... |

| HOLDING A WORKPIECE With routing, perhaps more than with other branches of woodwork, holding the workpiece is sometimes the most difficult part of Read the full article... |

| CLAMPS Quick-release clamps for jigs and templates For quick and easy positioning and moving of jigs and templates, quick-release clamps, e.g. Read the full article... |

| POWER SOCKETS With multi-sockets, label the plugs on your machines and power tools so that when, for example, you unplug the router Read the full article... |

| NON SLIP FLOOR A slippery floor is a major workshop hazard. We treated my chipboard floor by coating it with floor varnish and Read the full article... |

| DUST EXTRACTION With the dust extractor fitted to your router for hand routing, extraction will be much better if the extractor follows Read the full article... |